By Farhia Hussein, fab production supervisor

SkyWater’s cleanroom technicians are essential in manufacturing semiconductors, or computer chips, that are used in almost everything today — from electronics, cars and medical devices to home security cameras and our U.S. national security systems. To help with the chip shortage and fabricate more crucial chips, we need to hire more cleanroom technicians.

Curious about this important career? We sat down with Farhia Hussein, fab production supervisor with 17 years of experience with SkyWater and MVP award winner, to look at the day-to-day responsibilities of the role within SkyWater — and how it’s a great fit for a range of people — from newly graduated high school students and current college students — to artists who want a steady income, while also pursuing their passions.

You need a high school diploma or GED, and you need to be 18+ years old to be a SkyWater cleanroom technician.

People who want to work in a high-tech, fast-paced environment — and who want to learn and can follow clearly defined processes — will be a great fit for this role! If you can stay on your feet and walk around, we will teach you everything you need to know to be successful. There is a lot of movement, so you should eat right, get your rest, and wear good shoes (reimbursed by SkyWater).

Come as you are

SkyWater’s cleanrooms are cleaner than a hospital surgical room and allow you to wear casual clothes — even shorts and a t-shirt. It’s very freeing! You don’t have to have a certain look to come work. It’s very basic: wash your face and brush your teeth. There is no makeup or perfume allowed in the cleanrooms, because those products have the potential to contaminate the chips. SkyWater supplies your cleanroom attire which is sometimes called a “bunny suit.”

What do cleanroom technicians do?

Now that we’ve talked about the basics, let’s go to work! U.S. Representative Dean Phillips visited SkyWater to learn about fabricating the computer chips everyone needs. We will follow along as he learns what it takes to work as a SkyWater cleanroom technician.

- When you arrive, scan your badge at the security checkpoint.

- Store your lunch, personal shoes and personal items in your secure locker.

- Put on your building shoes.

- Clock in at a time clock.

- Enter a gowning room.

Outside of each cleanroom is a gowning room where employees put on lightweight cleanroom apparel over their own clothing. To enter a gowning room, team members walk across a sticky mat that removes contaminants from their shoes. The gowning room is stocked with freshly washed gowns to prevent contaminants from being brought into SkyWater’s cleanroom.

What’s it like in a cleanroom?

Most people have never been in a cleanroom environment before, so when they first see the gowns and hoods it can be intimidating. But when you go inside, the atmosphere is very comfortable, and not as strange as you think. The special garments protect employees, and are put on in the order below:

- Cleanroom gloves

- Bouffant/hairnet

- Hood (covers the hairnet)

- Safety glasses (Note: contact lenses are not permitted in the cleanroom.)

- Cleanroom gown

- Cleanroom boot covers (go over your building shoes)

6. Enter a SkyWater cleanroom.

SkyWater’s cleanrooms are carefully controlled environments with low levels of pollutants such as dust, airborne microbes, aerosol particles and chemical vapors — with tight control over temperature, humidity, airflow, noise, vibration and lighting. Not only is this environment necessary for the precise, quality manufacturing processes that SkyWater uses in the fabrication of semiconductors, it’s also a welcome relief for allergy sufferers!

7. Go to your assigned bay.

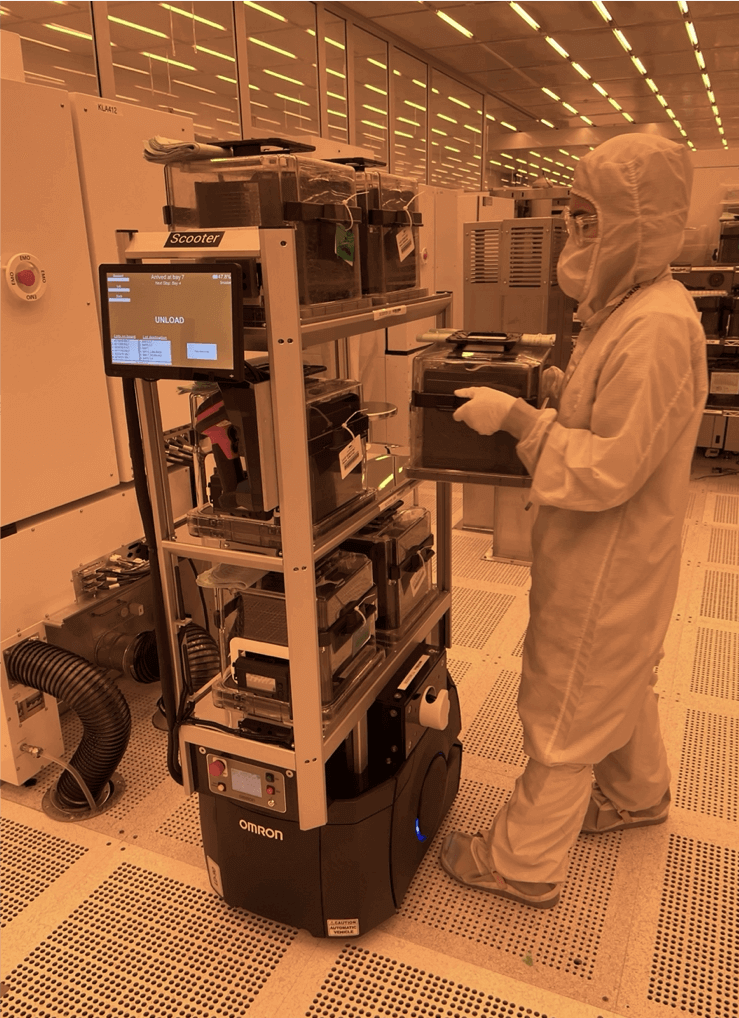

New hires will go to their assigned bay with a mentor for six weeks. All cleanroom technicians learn to operate support tools first, such as an electric track vehicle, which we affectionately call the Train. Once you are certified on support tools, you will learn how to operate wafer production tools. Depending on the tool, you can learn one or two tools per day. After training on a tool, you take an open-book test to enhance your tool knowledge as you then learn how to troubleshoot issues that could come up while operating tools.

To operate wafer production tools:

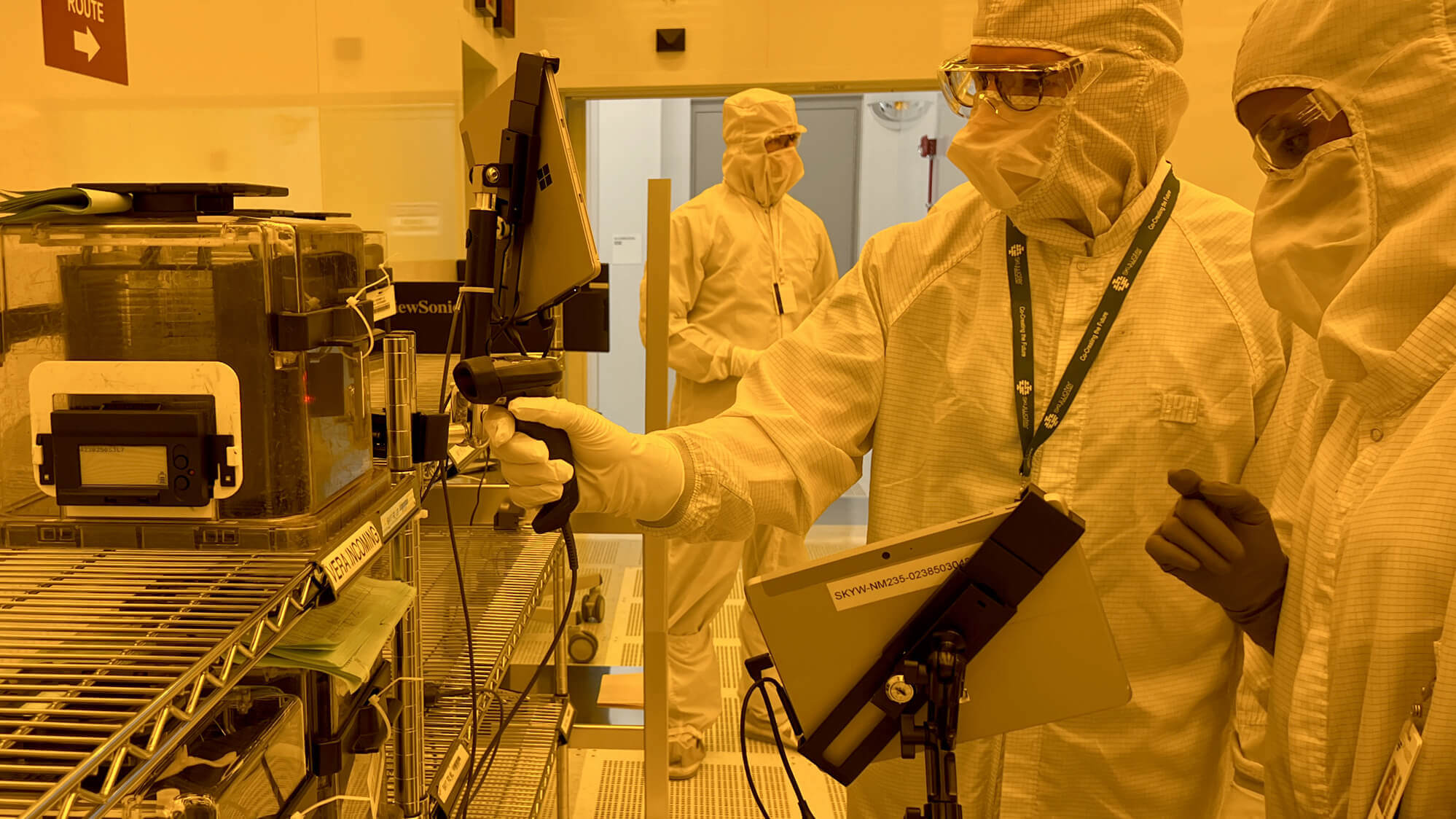

- Load wafer production machines according to the tools’ instructions.

- Unload wafer production machines when processing is complete.

- Scan wafer pods to show where they should go, which is displayed on an iPad.

- Pod transfers from one level of the cleanroom to another level are loaded onto the Train.

- Automated carts deliver wafer pods long distances on the same level.

- Cleanroom technicians walk wafers through the fab on carts for shorter distances.

- If issues arise, follow the troubleshooting procedures you learned in training.

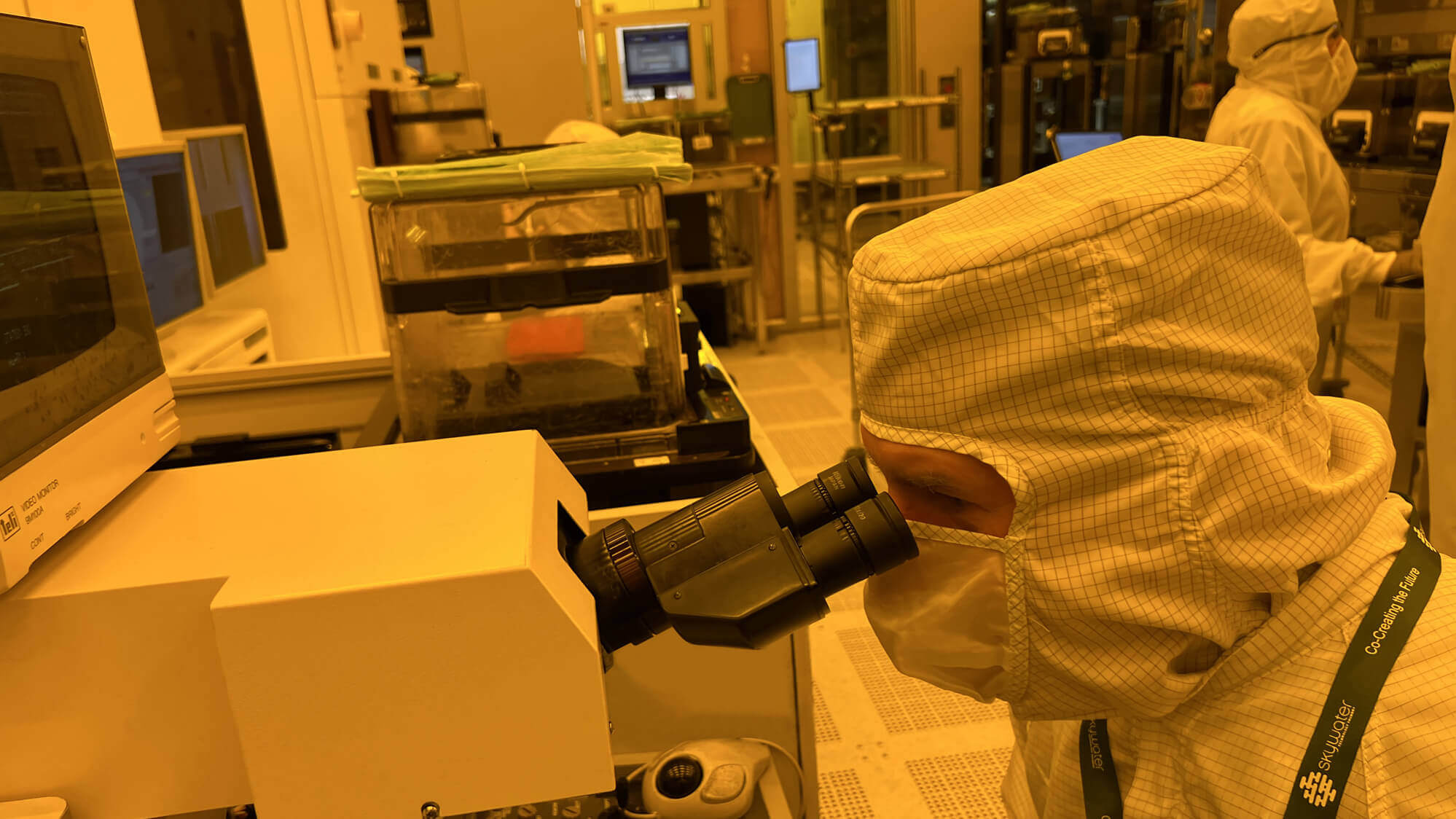

- Perform quality inspections on finished products.

8. As you are loading and unloading a wafer machine, if the tool’s alarm indicates that it’s down, send a message to support staff, maintenance or engineering.

Trainers are on the floor to help you — and every bay has a lead, a supervisor and a manager. Communication is key to our success. Not just inside the cleanroom, but throughout SkyWater. We have many avenues to communicate and people to help you succeed. For example, if you have questions about your timecard, benefits or vacation, you can easily message someone in human resources for help.

9. First half of your shift: take a 15-minute paid resting break.

Breaks are assigned by the lead to ensure coverage in each bay.

During the first six weeks, you perform the same type of work as experienced cleanroom technicians, but you will have more training to learn tools and therefore, test more frequently. For every tool set on which you are trained, you take a basic open-book test to show you understand. We hold five check-in meetings throughout new-hire training so technicians can ask questions, get shoes reimbursed, discuss the pace of training, ask any questions you have about your workstation — or anything else.

10. Mid-shift: half-hour, unpaid lunch break.

SkyWater offers meal deliveries via Foodsby so that you can schedule to have meals delivered. There are also refrigerators and food vending machines in the breakroom — along with a ping pong table, puzzles and assorted games. In addition, employee activities such as ice cream socials and food truck events happen throughout the year.

11. Training never stops.

It is ongoing, so you are always learning and growing in your role. Once you are assigned a tool — you own it. You make sure it’s running correctly and get to know assigned maintenance and engineering staff for the tool. Beyond training on your assigned tools, SkyWater also supports continuing education through tuition reimbursement and an apprenticeship program.

12. Take a 15-minute paid resting break.

Throughout the day, what happens if I need to go to the bathroom? Just go. Let your lead know. There’s no signing out and back in again. You ungown when leaving the cleanroom, and then re-gown with new gloves when re-entering.

13. During your shift, you may perform scheduled quals, which is short for qualifications, to check tools’ health.

Quals are set up by SkyWater’s engineering staff — so there’s no guesswork. You simply follow the procedures learned in training.

14. Hand off to the next shift.

When you’re a new cleanroom technician, reporting is done by the leads — and we encourage one-on-one communication with the next person who will work on the same tool. This usually happens organically. Shift to shift, bay to bay — no one skips a beat. We want to seamlessly roll into one another.

15. Ungown by taking off your cleanroom boot covers, hood and gown — and put them into a basket for laundering.

Your used hairnet and gloves can be thrown in the garbage. Safety glasses can be returned to your hook/storage area in the gowning room to reuse each day.

16. Clock out.

Rest, eat well, and get some good sleep! You’ve learned a lot, helped us manufacture essential chips, and we look forward to seeing you tomorrow.

What shifts are available at SkyWater?

There are four 12-hour shifts available for SkyWater cleanroom technicians. When you work four days in a row, you then get three days in a row off. When you work three days, you get four days off in a row that week. Check out our cleanroom technician openings and apply for a shift.

- Days/Shift A Sunday through Tuesday and every other Wednesday 6 a.m. – 6:15 p.m.

- Days/Shift C Thursday through Saturday and every other Wednesday 6 a.m. to 6:15 p.m.

- Nights/Shift B Sunday through Tuesday and every other Wednesday 6 p.m. – 6:15 a.m.

This shift offers a 10% shift differential, which means we will pay you an additional 10% to work Shift B. - Nights/Shift D Thursday through Saturday and every other Wednesday from 6 p.m. to 6:15 a.m.

This shift offers a 25% shift differential, which means we will pay you an additional 25% to work Shift D.

How much does a cleanroom technician make? To start, new cleanroom technicians will receive a $1,500 sign-on bonus.

The sign-on bonus pay-out schedule is $500 at 30, 60 and 90 days post start date. Our fab operates 24/7/365 days per year. Entry level technicians start at $17+ per hour with no experience necessary. Overtime is always available — so once you are certified, you can pick up additional shifts. Learn more by visiting the cleanrooom technician page.

Why Stay at SkyWater for 17 Years?

We asked Farhia why she continues to stay at SkyWater to grow her career. Her smile grew as she explained:

“I love the schedule. I have kids, and it’s so much fun having them for four days and then three days in a row. I love the fast pace.

Growth opportunities are available from the moment you walk in.

As a new employee 17 years ago, I had no idea what wafers were or what this kind of business SkyWater is — but I could see the growth opportunities. I learned a lot. I grew within the company to become an expeditor and then to my current role as a supervisor — and still there is so much more room for growth.

I love a nice, stable job with many different career paths.

Co-workers who hired on with me continued their careers with SkyWater by going into IT, maintenance and engineering — going back to college and growing with SkyWater. There are amazing opportunities if you put in the work.

I stay because training is ongoing.

We have in-house training through SkyWater Skills trainers who offer classes such as People Leader One and People Leader Two — so you can become a great leader. When I was a SkyWater expeditor, I attended off-site classes where I learned about spreadsheets and other management tools. The best thing about our internal training is that the classes are focused on SkyWater and you learn what to do in your specific situation vs. a generic class.”

‘I stay at SkyWater because I am happy, satisfied and comfortable where I am,’ concludes Farhia.