SkyWater and Weebit Nano have been working together for several months following the announcement of our agreement through which SkyWater will take Weebit’s ReRAM Non-Volatile Memory, or NVM technology, to volume production.

We sat down with Ross Miller, VP strategic marketing & business unit at SkyWater, and Eran Briman, Weebit Nano’s VP of marketing and business development, to understand more about the partnership and hear about what’s next.

Can you give us a quick overview of Weebit Nano and what the company provides?

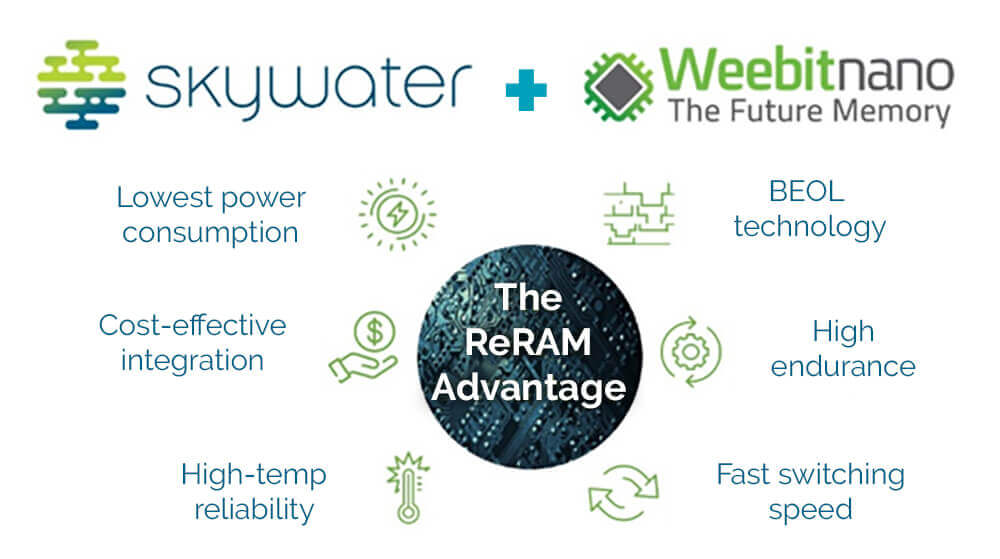

Eran: Weebit Nano is a developer of Resistive RAM, or ReRAM — a new type of NVM. Up until now, the standard for this type of memory has been flash technology, but with the emergence of new applications, skyrocketing data movement and storage needs, and tightening cost and power constraints, the industry is looking for a new type of NVM.

Weebit was founded to provide NVM that is higher performance and lower power than flash and has a long list of other advantages. A key consideration from the outset of the company was ensuring the technology would be commercially accessible, so our ReRAM is based on the most common materials and equipment used in fabs today. This makes it low cost and easy to integrate into existing flows and processes.

What are Weebit and SkyWater doing together?

Ross: SkyWater helps our customers bring new ideas to market with differentiated technologies, materials and processes. To this end, we partner with companies like Weebit that have bold ideas, solid technology, and the ability to have a big impact on our customers’ designs. Weebit ReRAM is an innovative emerging technology that is at the forefront of NVM. Now it is reaching maturity and approaching volume production.

SkyWater will initially offer Weebit ReRAM to customers as embedded NVM IP on our 130nm CMOS process. The technology can also be scaled in the future to a number of other platforms such as our 90nm and carbon nanotube CMOS technologies. The Weebit team has a great deal of commercialization experience, making the process quite straightforward as we move toward production.

Can you tell me a little bit about the applications where you see Weebit’s ReRAM being a good fit initially?

Eran: Since nearly every electronic product requires NVM, and ReRAM enables semiconductor memory elements to be much faster, lower cost, more reliable and more energy efficient than those using flash, target applications are extremely broad and diverse. Some initial applications where we see ReRAM being adopted are industrial, automotive and aerospace & defense.

Ross: SkyWater’s 130nm process, where we’re first rolling out the Weebit technology, is a sweet spot for a broad range of mixed-signal designs like analog, power management, sensors as well as rad-hard designs. Because ReRAM has such low power consumption and integration flexibility, we see a lot of interest in the near-term in IoT and general mixed-signal / ASIC designs.

Can you explain why ReRAM is a good fit for some of the vertical market segments? Let’s start with aerospace and defense.

Ross: Aerospace and defense applications are among the most demanding, requiring extremely high levels of precision and accuracy. ICs for aerospace and defense also have unique requirements for robustness and reliability in harsh environmental conditions. Since these products must often last for years – mostly without maintenance – longevity is another key trait.

Eran: Weebit ReRAM provides excellent endurance and retention even at high temperatures, retaining data for up to 20 years at 175 degrees Celsius. It can also withstand 350x more ionizing radiation than flash. If you’re designing a product today with flash, it’s going to require extra design for redundancy or shielding, and this isn’t needed with ReRAM. Our technology also has advantages over other emerging NVMs like MRAM such as cost, access time and immunity to electromagnetic fields.

What about industrial and automotive applications?

Ross: Both industrial and automotive ICs must be designed for safety and longevity, as well as robustness against vibration, humidity, extreme temperatures and other harsh environmental conditions. In rechargeable-battery applications like electric vehicles, there is also a need to withstand electromagnetic interference. The key with safety-critical industrial and automotive technologies is using proven, solid technologies. SkyWater’s proven analog/mixed-signal process technologies are a great fit for both industrial and automotive ICs, and we’re able to provide a high degree of customization needed to enable highly differentiated products.

Eran: The number of chips across the car and industrial environments continues to increase. Most of these chips require NVM, whether it be for trimming, code storage, or data logging. Key considerations are fast boot and code execution, handling frequent updates, and responding instantly even during power loss. For the growing number of small, low-power sensors that are often in remote and inaccessible locations, embedded NVM must also have ultra-low power consumption, and the performance to enable the shortest possible active power usage. Along with the excellent retention and endurance that Ross mentioned, this is what ReRAM offers.

Where do you see ReRAM going in the future?

Eran: As discussed, there is a broad and growing opportunity for ReRAM to replace flash across a broad range of applications. A bit longer term, one of the exciting opportunities is in neuromorphic computing where ReRAM isn’t acting as a traditional NVM, but also as a computing element. Today’s AI uses artificial neural networks to simulate brain function, but with neuromorphic computing, we’re talking about true brain inspired AI systems. Since a ReRAM cell physically resembles a biological synapse, it has functional similarities as well. This means that emulating neural networks with ReRAM consumes orders of magnitude less power than today’s neural network simulations.

Weebit has been working for several years with a number of global academic institutions toward ReRAM-based neuromorphic computing. A couple of years ago, together with our development partner CEA-Leti, we were the first to demonstrate ReRAM based spiking neural networks, and now we’re working on the next generation of this. Industry-wide, we’re starting to see neuromorphic developments moving from academia into commercial companies – both established and startups. With this move, ReRAM-based neuromorphic computing might be closer than people think.

Ross: ReRAM fits with SkyWater’s vision for the future as we look toward technologies that will enable differentiation and advanced performance the market demands. Consumers have a growing expectation of more capabilities and functionality at the same cost, so on-chip integration continues to increase. The natural evolution of this is toward hybrid monolithic integration, combining for example a MEMS structure or photonics device on top of a CMOS wafer. Or layers of carbon nanotube-based CMOS with layers of NVM.

Because ReRAM is a back-end-of-line, or BEOL technology, it can be integrated at various points in the fabrication process. And because it can be used as a computing element as well as an NVM, there is the possibility to increase density and bring more device-level capability to designs. Weebit ReRAM is a rich building block for hybrid architectures that can be flexibly integrated in new and interesting ways, making it a really exciting option for innovators as they look to bring new ideas from concept to reality.

SkyWater has a lot of experience in this area with the work we’ve done with MIT on Darpa’s 3DSoC architecture. That work showed the viability of this type of paradigm-shifting solution. Now with Weebit ReRAM we can make it a commercial reality.

Where do you stand in the technology transfer process, and when can customers get started?

Eran: Since announcing our partnership we’ve been working together with Weebit’s R&D partner CEA-Leti on transferring the Weebit ReRAM technology to SkyWater’s production fab. This process is moving forward smoothly as planned and once it is completed, qualification can begin..

Ross: As soon as the initial qualification is complete, SkyWater customers can have the confidence to tape-out their designs with ReRAM. Customers should reach out to us now to learn more about how ReRAM can help differentiate their solution for their specific application.